November 24, 2015 Updated 11/24/2015

Email Print

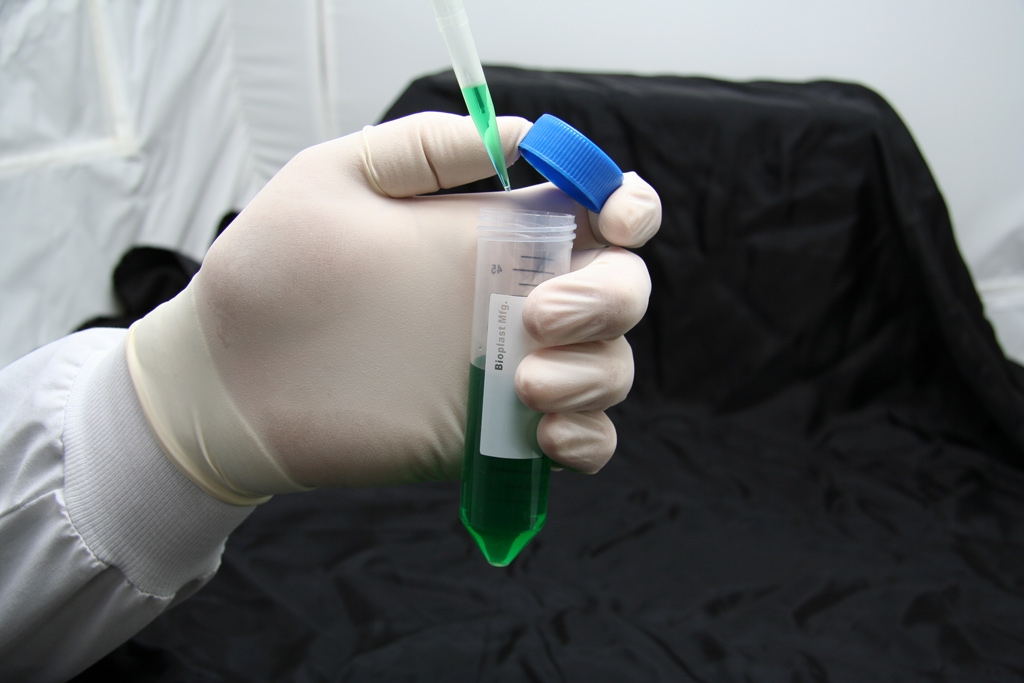

BioPlast Manufacturing LLC BioPlast Manufacturing LLC, a maker of pipette tips and other medical disposables, has adding assets to injection mold PS petri dishes.

BioPlast Manufacturing LLC has expanded its line of plastic laboratory disposables by acquiring Kord-Valmark’s manufacturing assets for injection molded polystyrene petri dishes.

BioPlast will move the acquired operation to its Bristol, Pa., headquarters plant by mid-2016, BioPlast director of operations Brian Conway said in a phone interview.

“This is a great mix,” Conway explained. “Petri dishes were an outlier for the former owner and they fit us because we do nothing but laboratory disposables.”

BioPlast will move nine injection presses with clamping forces of 50 to 300 tons to Bristol from the Kord-Valmark facility in Sandusky, Ohio, Conway said. The Bristol plant already has similar molding capabilities. Employment there will double to about 30, Conway said. Bristol’s manufacturing includes clean rooms, a high degree of automation and stack mold technology to produce high numbers of small laboratory disposables, mostly made of polystyrene but also including items made from polypropylene, high density polyethylene and elastomers.

BioPlast was founded in 2009 in Hamilton, N.J., and moved to bigger quarters in Bristol in 2013. It is a family owned business that injection molds pipette tips and other disposables for medical research, clinical, diagnostic and biotechnical applications.

Kord-Valmart’s other products, including plastic and metal medical cabinets, bins and storage containers, are not included in the Nov. 23 acquisition. BioPlast will continue marketing the petri dishes under the Kord-Valmart name. Kord-Valmart is part of Akron, Ohio-based Myers Industries Inc., a conglomerate in plastic and metal material handling products and fuel tanks. In early 2014 Myers sold its plastic lawn and garden products operations.

Conway said moving the petri dish molding business to Bristol will improve efficiency and cut order lead times.