February 2, 2016 Updated 2/2/2016

Email Print

Kush Bottles Inc. The founders of Kush Bottles Inc. developed packaging specifically for legal marijuana sales.

Plastic marijuana packaging has become, ah-hem, a growth industry.

With more than 40 percent of all states already allowing medical marijuana, and four of those also permitting recreational use, the packaging for Panama Red, Acapulco Gold and all those other colorfully named strains is heavily dependent on plastics.

Both flexible and rigid packaging helps keep the nation’s stash fresh for both the casual smoker in Colorado, Washington, Oregon and Alaska and medicinal users in 23 states.

And those packages aren’t just holding marijuana plants, as there are a whole host of edibles and concentrates for folks who don’t always, or ever, want to light up.

The prevalent pot brownie has long been a chewy, fudgy friend of the marijuana community. But these days, a whole crop of edible products have been developed to allow for the ingestion of marijuana’s active ingredient, THC or tetrahydrocannabinol.

Gummy bears. Chocolate bars. Granola. Popcorn. Even infused beverages can deliver THC.

“This side of the industry is huge. We call them edibles. They’ve proven to be very popular and a lot of people buying them,” said Chris Walsh, managing editor of Marijuana Business Daily, which reports on medical marijuana and retail cannabis. Those edibles are commonly found in one type of plastic packaging or another.

“Plastic is a huge part of the packaging dynamic in the cannabis industry, and it’s only getting bigger,” Walsh said. “And that’s because a lot of states are finally introducing regulations around packaging.

“They have a bunch of requirements now, and it really varies by state. There is no one standard across the industry,” he said.

And that’s where companies like Kush Bottles Inc. make their mark.

Kush, based in Santa Ana, Calif., dates back to 2010 and was formed by entrepreneurs Nick Kovacevich and Dallas Imbimbo. The two had sold a moving and storage building they had started in college and were looking for their next big thing.

It ended up being weed. More specifically, packaging for weed.

“People were flocking to these medical marijuana dispensaries and purchasing a ton of product. We wanted to get involved,” Kovacevich remembered about when medical marijuana began to flourish.

“One of the things we noticed right away was the packaging was a good niche,” he said. “It kept us on the packaging, plastics side which was a more stable, secure, less gray area. But it got us in the door with the growth of the industry.”

He estimated that about 60 percent to 65 percent of all marijuana packaging his company sells is made from plastic.

Kush has become one of the most recognizable names in the marijuana packaging industry. But make no mistake, there are plenty of other companies out there looking for a piece of the action.

A need for something unique

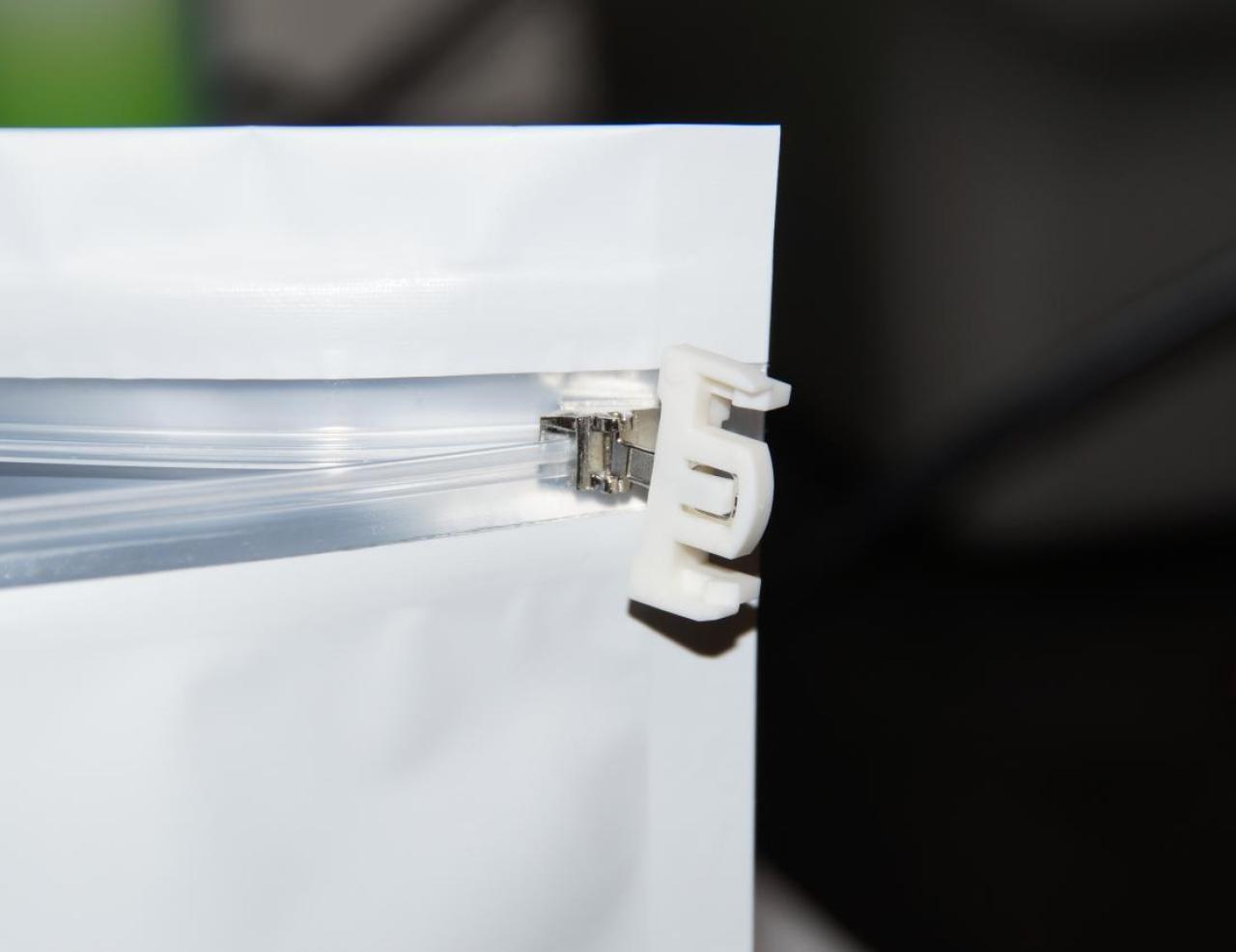

ABC Packaging LLC ABC Packaging produces flexible film packages with child-proof closures.

A baggie or an old pill bottle just isn’t going to cut it any more — at least on the legal side of the business.

ABC Packaging Direct LLC, based in Westlake, Ohio, is a sales representative for a variety of factories making barrier film and bags. The company started noticing an unexpected spike in orders five or six years ago before finally figuring out they were tied to the California marijuana trade.

And as more states approved both medicinal and recreational use of the drug, ABC started paying more attention to that portion of its business.

“We really sunk our teeth into it over the last couple of years,” CEO David Marinac said. “We didn’t set out to get involved in the marijuana business, the cannabis business. We happened to be in that world of flexible film or barrier packaging.”

But now that ABC has gained experience in that portion of the business, it certainly is trying to make the best of the opportunity.

“We look at it from a business side of things. We don’t judge anybody. That’s not our world. We provide packaging for anything from dog food to spices and cereal and bakery mixes. To us, it’s another product and we look at it specifically as another product,” he said.

“We don’t really jump into whether we support it or legalize it or whether it should be legalized. That’s a personal standpoint,” he said. “It’s a product that needs to be protected.”

Admittedly, Marinac said, being in the marijuana packaging business is “just different.”

“It’s not something you have a conversation over dinner all the time,” he said. “It’s a hot potato. It’s one of those things.”

Flexible packaging sold by ABC for marijuana is typically a multi-layer structure that can include PET, aluminum foil and linear low density polyethylene. “It’s probably going to be a three-to-five layer structure to be able to make that bag,” Marinac said.

Child-proof locks are sometimes required on the packaging, depending on the amount of product being sold.

“Now you’ve got the most advanced childproof packaging out there that I’ve seen on a consumer type good,” Walsh said. “I know adults that have struggled to get some of these things open.”

While flexible packaging is playing a significant role in the marijuana industry, rigid plastic packaging also has a large share of the market.

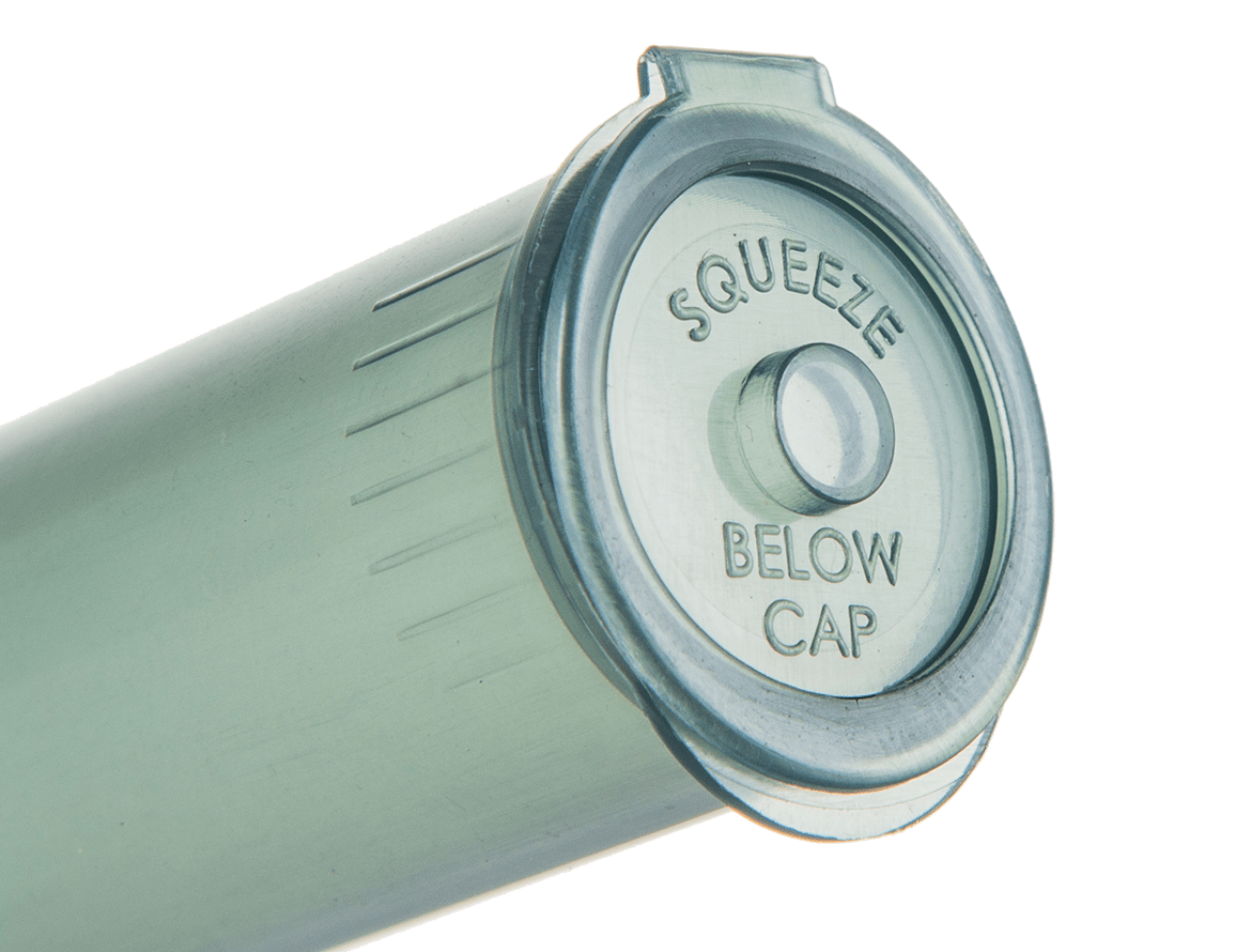

Marijuana also is commonly purchased in rigid “pop top” containers. These polypropylene units have an attached lid that pops off when pressure is applied on the side walls.

“It’s rigid. It’s not going to get crushed,” Kovacevich said, and almost completely air tight. “It’s something that comes in many different shapes and sizes and colors. When you are talking about different quantities, it can go across all your lines. So that’s why that product has always been a top seller and very popular.

“Plus it’s different than a traditional twist-and-turn bottle which you would get at the pharmacy. … The culture between pharma and traditional medicine vs. more of the counter-culture marijuana grass roots movement, it’s completely different. So why would anyone in the marijuana industry want to associate themselves with the pharmaceutical industry?

“That’s another reason why it’s popular, because it’s different and unique,” Kovacevich said about the plastic pop-tops.

Polystyrene containers with screw top lids — similar to those used in the cosmetics industry — also have a place in the industry as they are used to store and transport marijuana concentrates such as wax and oils.

A multi-billion dollar business

Kush Bottles Inc. A Kush polypropylene “pop top” container.

By Walsh’s estimate, the legal marijuana business had sales of about $ 3 billion last year, and that could soar to $ 8 billion by 2018 as more and more states approve both medical and recreational use.

Using trickle down economics — famously backed by President Ronald Reagan — the entire value of the market was $ 10 billion to $ 11 billion last year, Walsh estimated. And that figure could grow to $ 25 billion to $ 30 billion by 2018.

Plastic packaging, while just a component of the industry, appears to be ready to benefit from that growth. “If packaging accounts for a fraction of that, it’s a huge market still,” Walsh said. Estimates from Marijuana Business Daily put the value of about $ 15 million last year. “That will probably grow by leaps and bounds over the next couple of years.”

Marinac sees the market and agrees: “This is a very hot product that is out there. Whether you agree with it or not, that doesn’t matter. There is a serious market that is out there that wants packaging, whether it’s pure marijuana or edibles.”

He equated marijuana packaging to coffee bags, which have to seal in odors while also protecting the product from moisture.

“We see this as a potential serious growth market. We see this with a considerable amount of potential out there. Goodness gracious,” Marinac said.

Advances in plastic marijuana packaging are helping retailers and growers build particular brands thanks to customization.

Packaging also is moving toward single-serve portions for some edible products, a move that helps consumers regulate their intake.

“In the past, you might have bought a chocolate bar and you would only eat a piece of it. But you would have people were eating half of it and didn’t know better and couldn’t move for five hours,” Walsh said. “The packaging market is one of the main growth areas of the ancillary side of this industry.”

Kush just went public at the beginning of 2016 and trades under the stock symbol KSHB on the OTC market. The company, in January, reported quarterly sales of $ 1.72 million for the three months ended Nov. 30. That’s a steep increase from the $ 620,000 in sales for the same quarter a year before.

The Kush CEO said the goal in becoming a public company is to access investors interested in helping the company expand and grow.

“That’s our next push, going out there, knocking on doors and figuring out who is going to be our capital fundraising partners moving forward,” he said. “Take some capital into the company, use that capital to grow, invest that capital into new products. Invest back into development.”

Kush chiefly relies on outside suppliers for its lineup of products, but uses JB Plastics Inc. of Irvine, Calif., to manufacture its own patented, injection molded plastic joint and blunt tubes.

For the uninitiated, a joint is a smaller marijuana cigarette while a blunt is a hollowed out cigar that’s then filled with marijuana.

JB Plastics manufactures a range of bird repellant products for its sister company, Bird-B-Gone Inc., but owner Bruce Donoho seeks outside work as well.

“There’s capacity in our plant, so we’re always looking for a nice mix of both propriety products and contract work,” he said.

“We’ve been working with Kush for about two years now,” he said. “It’s classified out here as medicine. So I think there’s a lot of good therapeutic properties behind it. For a number of reasons it gets a bad rap. Quite frankly, I think that alcohol is a lot worse than marijuana,” Donoho said.

“Our motto since 2000 is ‘if you can dream it, we can make it.’ We lend ourselves to a lot of entrepreneurs. So we see a lot of entrepreneurs and believe in giving those types of people an audience. It’s worked well for us over the years,” Donoho said.

“I see that there’s so many more people who want to buy America vs. Chinese for a myriad of reasons. That really serves us well, being made in America,” Donoho said.

Kovacevich hopes to use investors’ money to develop more exclusive designs and products. “That’s what we’re all about, and it takes capital to do that,” he said.

These kinds of innovations will help companies build their brands, Kovacevich said.

“People are now open to the idea of getting into custom solutions. We have to focus on compliance, because that’s No. 1, we need to have compliant packaging. But sometimes compliant packaging comes at the cost of building a brand,” he said. “We can help them build their brand along with helping them operate compliantly.”

Kush, itself, didn’t have to look too far for its own branding, its CEO said.

“Kush Bottles is a name that we came up with because it has a nice ring to it. Kush is a very potent form of marijuana,” Kovacevich said. “Kush is a well-known term within the industry. But outside the industry, it’s also something that people who are involved or aren’t familiar with the industry may not know, may not make the connection. Which we thought was cool because it felt like more of an insiders club.”