February 19, 2016 Updated 2/19/2016

Email Print

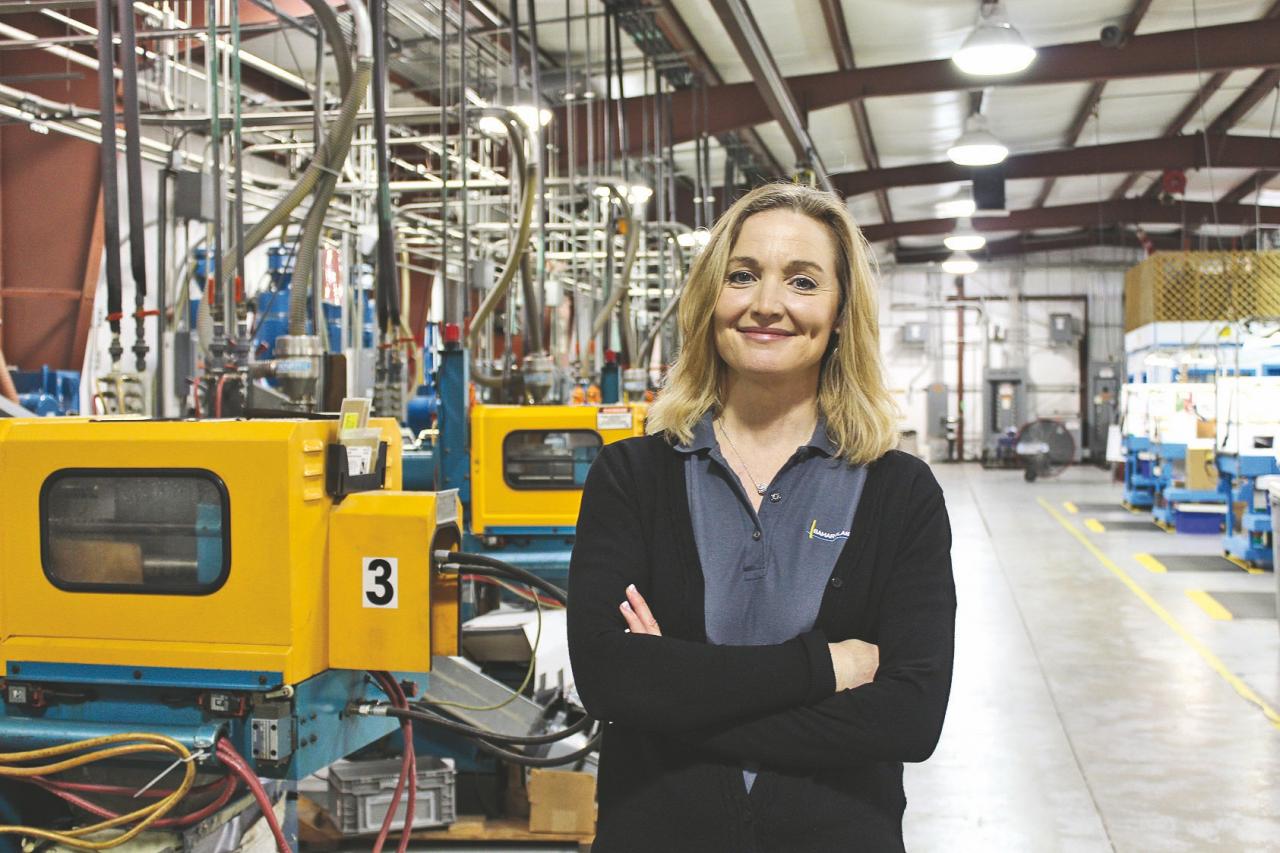

Plastics News photo by Jeremy Carroll Heather Lee Meixel has taken over Bamar Plastics, a company that her father started in 1978. The small processor has made several investments recently, including a new press.

South Bend, Ind. — It would a mistake to judge Bamar Plastics Inc. by its exterior.

Sure, the neighborhood appears a little rough and the signage to the building has faded. But inside, visitors — and there’s been plenty of late — will find a fiercely loyal employee base and an injection molder itchin’ to grow.

Meet President Heather Lee Meixel. The 47-year-old took over just seven months ago and will soon be the sole owner nearly two years after her father and company founder, Barry Lee, passed away from natural causes. Lee Meixel has experience in industrial sales and an easy smile, which allows her to fit in with her friendly and long-tenured staff.

“Some of the stuff Dad’s left with me, first and foremost, is to take care of people who work here. He handpicked everyone that’s here. Just about everybody’s been here between two decades and three-and–a-half decades. Keeping people is not a problem,” said Lee Meixel, a Purdue graduate who majored in economics thinking that an attorney’s life was in her future.

Bamar has 27 employees and $ 2.2 million in sales mainly from the automotive sector. “Just about every make and model of a car has one of our parts in it,” she said.

While Lee Meixel would like to increase the amount of business Bamar generates in the auto sector, she is eager to diversify and grow its defense and assembly business. Bamar actually got its start in electronics with Barry Lee’s invention of two plastic bases that fit on the back of cathode ray tubes.

In the last year, Lee Meixel has walked consultants and potential partners through Bamar looking for an edge and an outsider’s perspective. “We’re already doing many good things. But I like to get other people’s ideas,” she said.

To modernize Bamar and, in turn, land more business, Lee Meixel knew she needed to invest in the company. She’s started with a 180-ton Engel press ($ 250,000), new water chillers and new desktops for office staff. All told, Bamar spent $ 500,000. Lee Meixel hopes to add 18 more presses in the next five years to replace the company’s Boy presses, some of which date to 1985.

Capital expenditures are only the beginning. Bamar has hired a marketing firm to remake the website and generate inbound phone calls. The funding came through a grant from the University of Michigan. Local school districts will be supplying a couple of interns this summer. Bamar hosted 30 students on National Manufacturing Day, too, with six of the kids scheduled to return at their own request for an extended look at industrial careers.

But Lee Meixel is most excited about Bamar’s new apprentice program. Bamar will work with Ivy Tech and WorkOne to educate and train a certified apprentice over the next four years, all funded by Bamar.

“We are definitely investing in the education. We are putting our money where our mouth is as far as building a qualified workforce,” she said, adding that this particular apprenticeship is for industrial maintenance technician and could pay $ 65,000 once the candidate comes through the program.

Bamar is only running at 30 percent capacity, running three shifts five days per week, including some lights out manufacturing. The new boss knows Bamar can generate $ 5 million in sales if it can run 24/7 every day.

“The communication flow is amazing. Any customer that wants to can talk to anyone on staff — inspector, press operator, vice president. It doesn’t matter. We’re very open. It makes us super accessible. Problems get solved very quickly,” she said.

Some business may come when Bamar becomes certified as a minority supplier, specifically a woman-owned business. Lee Meixel has Bamar in the process of certification by the state of Indiana’s Minority and Women’s Business Enterprises and the federal Women’s Business Enterprise National Council.

How does that generate business?

“Hopefully, being certified will be a tie breaker in certain situations. There are some companies that are mandated to employ supplier diversity. Those will be doors we get in. Once you’re on the other side, you have to bring the value as well. So, we’ve got that.”

Anything keeping Lee Meixel up at night?

“What keeps me up at night is making decisions that sustain Bamar. I want to see Bamar Plastics thrive into the future. … Making sure the company is here for the people who work here. That’s primarily our focus.”

And what would Barry Lee say if he were to sit down with his daughter today? “‘Keep it up,’” Lee Meixel said. “He’d probably say something like, ‘I can’t believe it. I’m so happy.’

“We’ve had a couple of jobs fall out of the sky. Somebody driving by the building to make sure we’re still open and calling us to give us work. Those aren’t leads you get every day. So I kind of think he may have had something to do with that, too.”