March 17, 2016 Updated 3/17/2016

Email Print

Molded Rubber & Plastic Corp., a medical device components and assemblies provider based in Butler, Wis., acquired injection molder Johnson Precision, which is in Hudson, N.H., to expand its capabilities and market reach.

Founded in 1981, Johnson Precision is a contract molder of medical devices that have high-precision molded components and sub-assemblies. The business has about 40 employees and will continue operations as a division of MRPC.

No other terms of the deal were disclosed but MRPC President and CEO Greg Riemer did explain some of the advantages the acquisition offers MRPC, which has been in growth mode for the last five years with the 2012 purchase of ETI Inc., a liquid silicone rubber molding company in Largo, Fla., and the 2014 expansion of its Butler headquarters.

Johnson Precision has in-house injection mold making — a service MRPC did not offer — as well as a Class 8 clean room. MRPC specializes in clean room molding with a focus on LSR, two-material and micro-molding. Now MRPC has seven clean rooms company wide.

In addition, Johnson Precision has a joint venture partner in Malaysia and both businesses are FDA-registered to produce finished medical devices. That opens the door to new business opportunities for MRPC in the Pacific Rim.

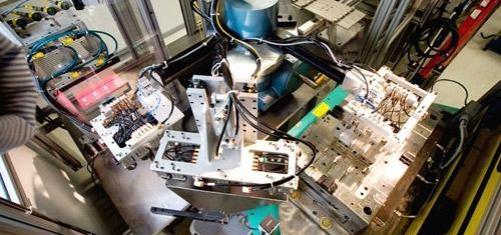

Molded Rubber & Plastic Corp. An automated molding cell at MRPC.

Then, there’s Johnson Precision’s reach in the United States.

“This facility’s New Hampshire location will support our customers in the Northeast while also adding to our ability to attract new business in that region,” Riemer said in a news release.

MRPC will continue its growth strategy of increased sales and acquisitions, Riemer added. Founded in 1921, MRPC now employs 200 people at its three facilities. The Butler headquarters got a $ 2.5 million, 15,000-square-foot addition in June 2014, which brought the facility to 100,000 square feet. MRPC officials said at the time that they expected business to grow at a rate of 10 to 15 percent per year into 2019 and would add 35-40 employees in the Milwaukee area during that period.

Last month MRPC added several injection molding machines to the Butler operation to improve process control capabilities and the quality of molded components. The new equipment includes two 180-ton Engel horizontal liquid injection molding machines for shot-to-shot consistency of liquid silicone rubber as well as a 40-ton Engel vertical shuttle thermoplastic molding machine for two-material components.