March 25, 2016 Updated 3/25/2016

Email Print

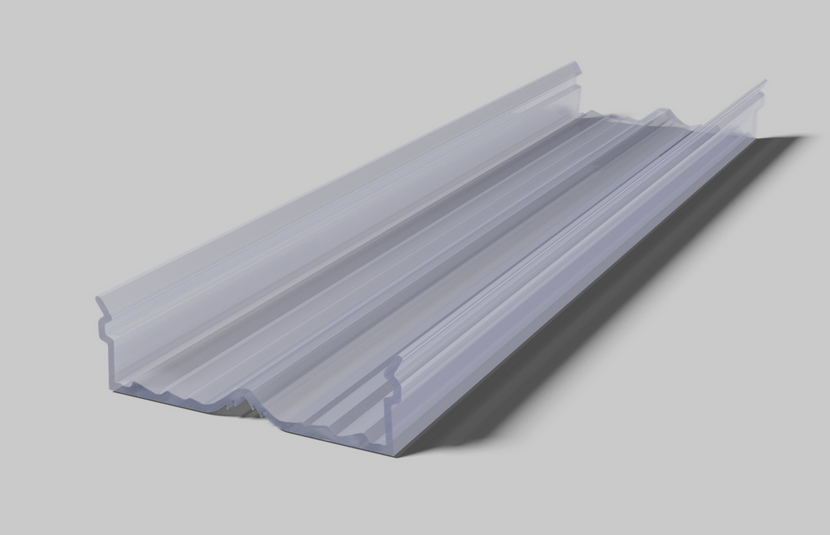

Rotuba Extruders Inc. Rotuba Extruders is developing a growing business line in producing custom shapes for LED lighting.

A boom in the LED lighting market, especially for profiles, is creating a rapidly growing market that Rotuba Extruders Inc. is positioning itself to satisfy.

The longtime family-owned company plans to add four extrusion lines in the next year or so to keep up with the profile business. That’s why it sold off its LED extrusion sheet lighting business to Plaskolite LLC in February.

“The direction of lighting has gone significantly to custom shapes,” said Adam Bell, president and CEO of Rotuba. He is the third generation of his family to lead the company started by his grandfather Walter Bell and continued by his father Albert.

“A bigger part of our business is custom profiles [since] LEDs are now taking over the lighting business,” he said.

Rotuba makes lenses and diffusers from acrylic and polycarbonate that are used in the lighting structures.

Bell said the Linden, N.J.-based company needs space within its 150,000-square-foot facility to facilitate growth in the profile lighting area, and that’s why he parted with the sheet business. He said the LED part of its business has grown about 30 percent a year over the past three years, while overall business is up 20 percent per year.

While LEDs have been replacing florescent lighting in recent years, Rotuba has prevailed because “we are one of few companies that can turn around a tool in 24 hours and then use it on seven different formulations,” Bell said.

He said the company uses a continuous process improvement system along with an emphasis on safety to build a solid reputation. Rotuba is able to change formulations directly on the production line.

“We’re doing six new projects a week — that includes design and tooling,” he said.

Rotuba relies on Davis-Standard extruders and currently runs 16 lines. It has 250 employees at two facilities.

The company was started by Walter Bell to make rods, tubes and bars for hand rails and even billy clubs back in the 1940s and has evolved ever since.

It now has three distinct areas of its business. In addition to extruded profiles for lighting, it provides raw materials from wood pulp called cellulosics — the powder is used for anything from tool holders to eye glasses and toys.

It also injection molds ball point pens used in hotels and for promotions. It bought out the Pen Co. of America, also known as Rotary Pen Co., about five years ago and runs that operation in Garwood, N.J.