May 13, 2016 Updated 5/13/2016

Email Print

Chris Sweeney

Rubber & Plastics News

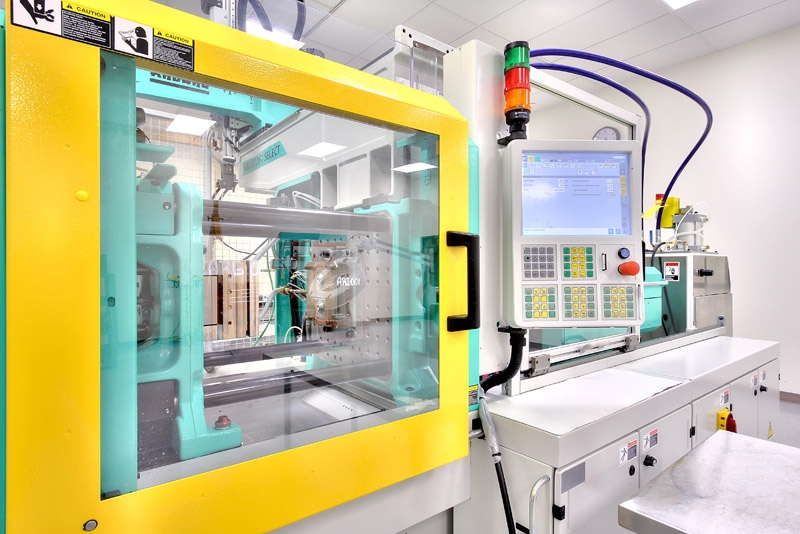

Elastomer Technologies Inc. Elastomer Technologies Inc. has added two liquid injection molding machines to keep up with demand.

Elastomer Technologies Inc. has expanded its capabilities through the addition of two pieces of liquid injection molding equipment.

The firm added an Engel 55-ton and a 110-ton Arburg in February, which doubled its molding capacity. ETI said both are equipped with robotics and were installed in its ISO Class 8 certified clean room, which previously housed two machines.

ETI of Corona, Calif., employs about 20 people, and President Randy Lester said the firm plans to add three more through the expansion. He added that ETI invested about $ 500,000 for the two machines.

“We’ve been given requests for quotes for parts that are beyond our capacity,” Lester said. “It was a good time to add the machines so we could participate in that business.”

He said the company has had LSR molding capacity since the early 1990s. ETI also has die-cutting, stamping, gaskets, compression and transfer molding capabilities. About 60 percent of the firm’s business comes from the medical field. It also services the aerospace, defense and recreational markets.

The firm is working toward more automation, and with the two new machines, it has the capability to run products 24/7 without interruption.

The 55-ton machine was brought in because of a project the firm landed a little more than a year ago and now needs higher volumes. Lester said a customer’s product already runs on one machine, and the new machine will house a revision of that product. The third machine was added to bring the firm capability to run larger parts.

ETI runs four LIM machines, 10 for the compression and transfer business and eight for die-cutting. The firm moved into its current 18,000-sq.-ft. facility in Corona about two years ago.

“We were just cramped where we were,” Lester said. “It was elbows to elbows. We had the opportunity to pick up this building we’re in now, and we spent about a year putting this building together, adding the clean room and doing all the revamping to facilitate what we wanted to do in here. We have a very clean facility; everybody who walks in here says it’s the cleanest molding manufacturer they’ve walked through.”

In addition to silicone, Lester said ETI works with all elastomers.

Plastics News Now: Boy smashes 3-D printed tumor replica