July 1, 2016 Updated 7/1/2016

Email Print

Nevhouse Pty. Ltd. Nevhouse Pty. Ltd. has delivered 15 buildings, made using a plastic and wood composite, to Tanna Island in the Pacific Ocean to help the community rebuild from Cyclone Pam.

An Australian company is building kit homes for a cyclone-ravaged Pacific island from laminated veneer lumber and a wood-plastic composite.

The design team’s ultimate aim is to use 100 percent recycled plastic to construct homes and other buildings for poor communities around the world that are affected by natural disasters, but it is still working on getting the right technology.

Brisbane-based Nevhouse Pty. Ltd. has delivered 15 buildings to Tanna Island, off Vanuatu, which was devastated by Tropical Cyclone Pam in March 2015.

Architect Ken McBryde, a principal with Hassell Pty. Ltd.’s Sydney design studio, told Plastics News he has been working with Nevhouse’s founder Nev Hyman for four years.

They initially assembled a team of polymer experts with the aim of developing a single composite extrusion to make floors, roofs, walls and louvers that could be flatpacked for export and easily assembled on site by people with minimal trade skills.

“That was the aim, but we found contaminants in the plastic wouldn’t give us long-term resistance to creep,” McBryde said.

“No matter which polymers we combined or additives we explored, for the long-term structural stiffness we need to make housing, we had to accept that recycled plastic waste really was just rubbish.”

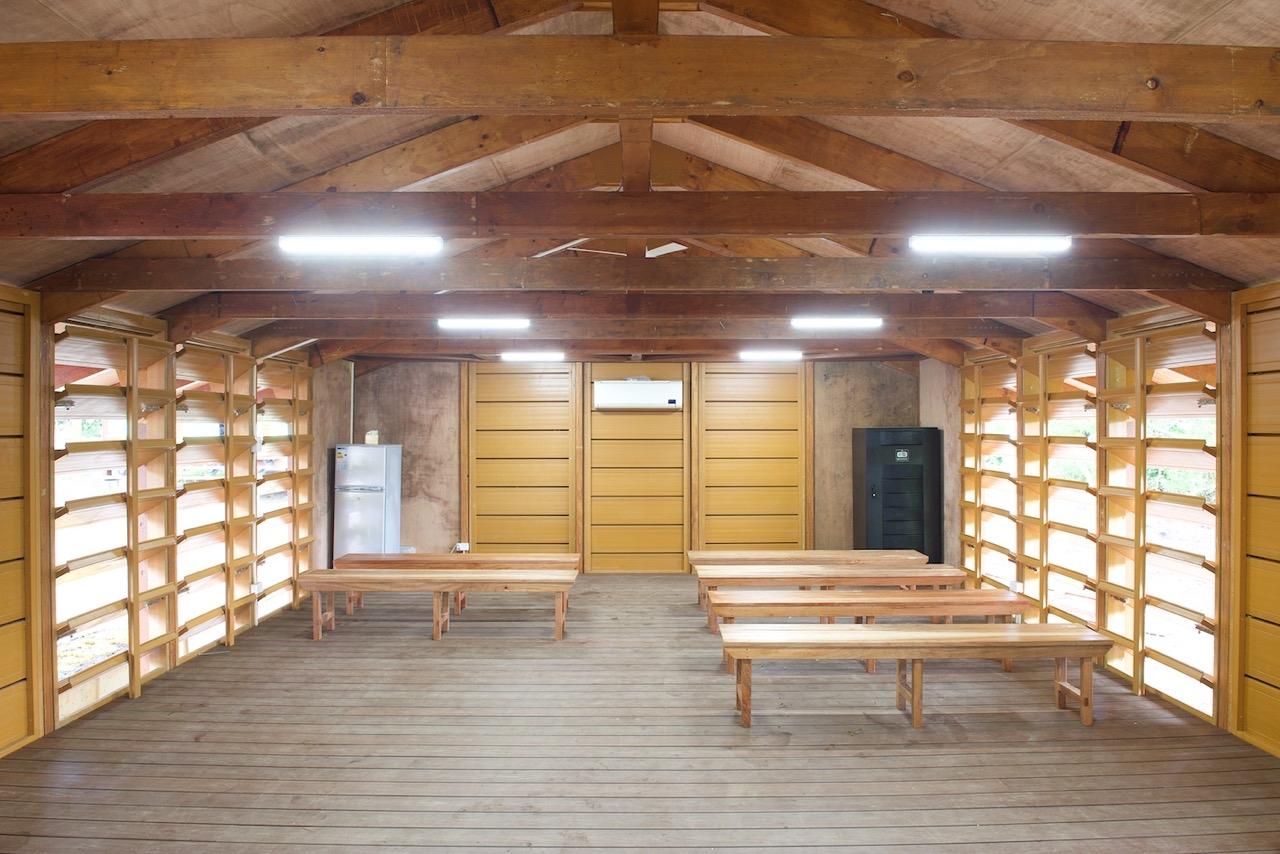

Nevhouse Pty. Ltd. The interior of a Laminated Veneer Lumber home.

McBryde said when Cyclone Pam hit, the Nevhouse team decided it could wait no longer to find a way to use 100 percent recycled plastic and instead reverted to a prefabricated laminated veneer lumber (LVL) frame system McBryde had developed 25 years prior while studying for a research master’s degree at the University of Queensland.

Nevhouse now uses LVL and a wood-plastic composite, made from recycled polyethylene and polypropylene, to build components for the houses.

Hyman told Plastics News the company still wants to use 100 percent recycled plastic material, but needed to get a product to market quickly after Cyclone Pam. “We are using plastic waste in the WPC and we’re proud of that,” he said.

The company is investigating using a low heat-high pressure system called powder impression molding (PIM), which will enable use of large volumes of agricultural, post-consumer and industrial plastic waste.

South Leigh, England-based Environmental Recycling Technologies plc (ERT) owns patent rights to the PIM process. Hyman said he was negotiating with ERT to have exclusive use of the technology to build homes.

The 15 buildings constructed on Tanna Island were financed by a Hong Kong-based philanthropic organization that wishes to remain anonymous. Hyman said the buildings cost A$ 1.8 million (US$ 1.3 million). They are community centers, classrooms and a medical clinic and double as cyclone shelters. Nevhouse also plans to provide homes for the Tanna Island villagers.

McBryde said the buildings are strong enough to survive another category five cyclone.

Hyman said other philanthropic organizations around the globe will finance future Nevhouse projects and there is no shortage of potential funds.

McBryde and Hyman, founder and now part-owner of Gold Coast, Australia-based Firewire Surfboards Pty. Ltd., met through their mutual love of surfing and realized they shared a desire to help poor nations.

“We need new mechanisms for the problems facing humanity,” McBryde said. “Business as usual won’t cut the mustard.”