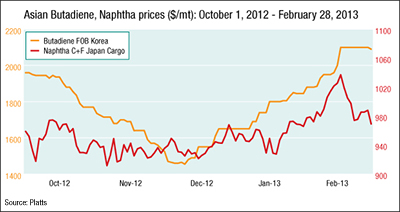

March 1, 2013 – Asian butadiene prices hit a more than six month high February 18 on tight availability amid the startup of new synthetic rubber plants in China and higher naphtha feedstock costs.

Butadiene prices surged 44% from a 2012 low of $1,455/mt FOB Korea on December 7 to $2,100/mt on February 18, Platts data showed February 19.

The last time the butadiene benchmark was that high was on August 3, 2012, when it stood at $2,239/mt.

Asian naphtha prices stood at $1,023.25/mt CFR Japan February 18, up 7% from $959.625/mt on January 2.

In China, the expected startup of new domestic butadiene rubber plants placed additional demand on butadiene supplies.

Sinopec Maoming is due to start up a new 100,000 mt/year BR plant in the first quarter, while Zhejiang Transfar plans to start up a 100,000 mt/year BR plant by the end of Q1. In Q2, YPC-GPRO (Nanjing) Rubber is due to start up a 100,000 mt/year BR plant at Jiangsu province, and Petrochina’s Sichuan Petrochemical plans to bring a 150,000 mt/year BR plant online by mid-year.

This follows the startup of new synthetic rubber plants in 2012 that resulted in China’s butadiene imports for the year soaring almost 47% year on year to 344,825 mt, data published late January by the China Customs Statistics Information Center showed.

One of those new plants was started up by German specialty chemicals maker Lanxess — a 30,000 mt/year joint-venture nitrile butadiene rubber plant at Nantong — on May 23.

Recent butadiene price hikes have also been supported by lower production in South Korea due to a change in feedstock composition and technical woes.

Lotte Chemical began using 10% LPG as feedstock for its steam cracker at Daesan from February 1 to cope with rising naphtha costs.

The Daesan steam cracker, which can make 1 million mt/year of ethylene and 500,000 mt/year of propylene, supplies crude C4 feedstock to a 150,000 mt/year butadiene extraction unit at the same location.

The change will not affect output of ethylene and propylene but will lower production of butadiene.

Similarly, Yeochun Naphtha Cracking Center plans to use 10% butane as feedstock for its No. 1 and No. 2 naphtha-fed steam crackers at Yeosu to 10% from March 1.

The No. 1 unit can produce 860,000 mt/year of ethylene and 450,000 mt/year of propylene; No. 2 580,000 mt/year of ethylene and 280,000 mt/year of propylene; and No. 3 470,000 mt/year of ethylene and 240,000 mt/year of propylene. No butane will be used in the No. 3 cracker.

The three supply crude C4 feedstock to a 240,000 mt/year butadiene extraction unit that is due to undergo a month-long turnaround in May.

That unit has been operating at 80% of its capacity since February 8, down from 100% earlier, due to contamination of an extractor caused by polymerization. This equates to the loss of a 1,500 mt butadiene cargo/month.

Also from March 1, Samsung Total will use 10% of butane as feedstock for its naphtha-fed steam cracker at Daesan, which can produce 1 million mt/year of ethylene, 600,000 mt/year of propylene and 114,000 mt/year of butadiene.

Source: http://www.platts.com/newsfeature/2013/petrochemicals/asia-olefins/index