As the demand-supply gap widens for natural rubber in India, tyre companies are increasingly resorting to imports to meet their requirements.

Take, for example, Apollo Tyres. It imported 45 per cent of net requirement in the first six months of this financial year. J K Tyre and Industries, another tyre maker, imported close to 25 per cent of its requirement during the period.

“Last fiscal, our natural Rubber importsvaried between 35-40 per cent of the total requirement, whereas in the first half of this fiscal, the imports went up to 40-45 per cent,” said Satish Sharma, chief of India operations, Apollo Tyres.

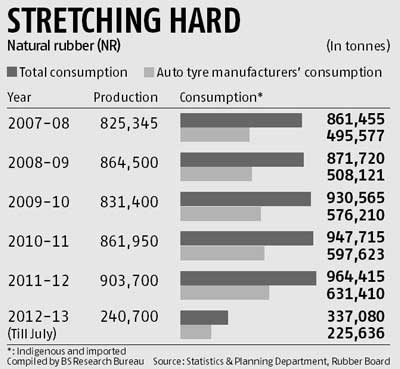

While the consumption of natural rubber rose 5.6 per cent in the first half of the current financial year, production went up only 1.1 per cent. User industries, especially the tyre segment, are resorting to imports owing to the supply crunch. These to 112,640 tonnes in April-September, against 91,186 tonnes in the corresponding period last year.

Said A K Bajoria, president and director of J K Tyre: “We are importing rubber from countries like Indonesia and Vietnam at present. In the last six months, we have imported around 25 per cent of our requirement, and the proportion is the same right now. We will see how prices move.”

The Rubber Board has projected annual production at 930,000 tonnes and consumption at over one million tonnes, with an annual deficit of 76,000 tonnes for the current year.

J K Tyre is on the lookout for small rubber plantations overseas to help with supply. “As far as acquisition is concerned, we are on the lookout. The process is on. (We) cannot comment on a timeframe when we will zero in on any asset,” Bajoria said.

Imported rubber is around three per cent cheaper than domestic rubber, he said, adding the impact on margins, however, is around 0.5 per cent. Rubber comprises 28-30 per cent of the raw materials that go into making tyres, the other ingredients being chemicals, carbon black, nylon fabric and crude oil. Apollo’s Sharma, however, pointed out the import of rubber had risen not only because of the demand-supply gap but also because it was of superior quality. “We are using imported rubber, which is superior in quality, for our radial tyres. And, the production of radials, both truck-bus and passenger car tyres, has gone up significantly this year.”

The tyre industry in India has witnessed some sluggishness in demand from original equipment manufacturers (OEMs). However, as tyre-makers are focusing on the replacement market and exports, the impact of dull OE demand has been partially offset.

“Despite the sluggish demand from OEMs, our focus on the replacement market has resulted in steady sales throughout the first half of the fiscal,” Sharma said. Even Bajoria added he expected the second half of the year to be better, compared with the first half as demand was likely to pick up on account of the festive season.

Source: Business Starndard