2013: demand growth margin dropped significantly

2013, the global economic situation further recovery, the domestic automobile and tire industries also appear rapidly growing trend, which is also driven by synthetic rubber demand growth has accelerated. But serious excess supply capacity, making the industry profit margin dropped significantly, device downtime, lowering the load is more prevalent throughout the synthetic rubber industry into the cycle trough.

As of the end of 2013, China’s synthetic rubber (seven basic types of plastic and SBCs, the same below) the annual apparent consumption of about 4.13 million tons, an increase of 6.3%, the growth rate increased by 1.6 percentage points over 2012, down from the car and growth of the tire industry. China’s synthetic rubber production capacity of 5.09 million tons, adding 970,000 tons for the year, average operating rate of less than 60%.Most products over last year prices fell by more than 20%.

2014: filled with low utilization rates within a narrow range

1. Synthetic rubber demand will continue to increase, the growth rate was essentially flat with last year

According to the relevant institutions predict that in 2014 China’s automobile production and sales of about 24 million, an increase of 9%, the growth rate slowed slightly. Car ownership continues to increase the amount of maintenance to replace increased market demand for rubber products, synthetic rubber will stimulate demand. 2014 China’s tire exports on the basis of 2013 the growth rate will slow down, and the United States on China’s recent off-road tires, motorcycle tires countervailing Brazil to China conducted anti-dumping sanctions will also affect exports tires and other products, it is estimated to remain above 10%. With the U.S. and European footwear exports will continue to increase as the economy improves.

2014 China’s synthetic rubber demand is about 4.4 million to 450 million tons, an increase of 6% to 8%, the growth rate of the previous year, or slightly faster.

2. Device utilization will remain in the doldrums

2014 domestic synthetic rubber Added ability to remain up to 74 tons, is expected by the end of the total capacity will reach 5.8 million tons. 2014 is the ability to add up to butyl rubber, adding 270,000 tons; followed by styrene-butadiene rubber, respectively, 180,000 tons and 130,000 tons.Following the 2013 butadiene rubber capacity of more than rubber, butadiene rubber 2014 domestic production capacity remains the largest types of plastic, its supply pressure will be greatest.

2014 China Synthetic Rubber plans to add capacity in Table 1.

Table 1 2014 domestic synthetic rubber plans to add capacity

|

Variety |

Company Name |

Project Location |

Ability |

Commissioning date |

|

SBR |

Baling Petrochemical |

Hunan Yueyang |

3 |

2Q-2014 |

|

|

Zhejiang WEITAI |

Zhejiang Sanmen |

10 |

2Q-2014 |

|

|

Liaoning Daina Suo |

Panjin |

5 |

3Q-2014 |

|

Subtotal |

|

|

18 |

|

|

BR |

Liao 宁胜友 |

Panjin |

3 |

2014 mid- |

|

|

Shouguang Fenghuiyuan |

Shandong Shouguang |

10 |

2014 second half |

|

Subtotal |

|

|

13 |

|

|

SBCs |

Liaoning Daina Suo |

Panjin |

5 |

2014 |

|

Subtotal |

|

|

5 |

|

|

IIR / HIIR |

Yanshan Petrochemical |

Beijing Yanshan |

9 |

1Q-2014 |

|

|

Formosa synthetic rubber (Ningbo) |

Ningbo, Zhejiang |

5 |

2014 year |

|

|

Shandong Jingbo Petroleum |

Shandong Boxing |

5 |

4Q-2014 |

|

|

Shandong rapture |

Guangrao |

3 |

4Q-2014 |

|

|

Eastar Holding Group |

Dongying |

5 |

2014 end |

|

Subtotal |

|

|

27 |

|

|

EPDM |

Sinopec Mitsui |

Shanghai Caojing |

7.5 |

2Q-2014 |

|

Subtotal |

|

|

7.5 |

|

|

IR |

Ningbo Jinhai De flag |

Ningbo, Zhejiang |

3 |

2014 second half |

|

Subtotal |

|

|

3 |

|

|

NBR |

Ying Sa Gimpo |

Nanjing |

3 |

2014 first half |

|

Subtotal |

|

|

3 |

|

|

Total |

|

|

76.5 |

|

With the rapid growth of production capacity in 2014 will remain China’s synthetic rubber plant utilization is low, especially butadiene rubber plant. 2013 new production of Maoming Petrochemical, Yangzi Gimpo, Zhejiang Communication 3 sets of 100,000 tons / year butadiene rubber plant operating load has been low, Qi Xiang Tenda 50,000 tons / year plant is also a long time in the parking test postpartum state. PetroChina Sichuan Petrochemical Company 150,000 tons / year butadiene rubber plant will be officially put into operation in February 2014. Ability to put a lot of focus on the supply, while demand is currently in the market trough, will inevitably bring about a significant decrease in device utilization.

In 2014 there will be five sets of butyl rubber plant put into operation, to the end of the ability to up to 44 million tons / year, domestic supply will also be greatly surplus. Coupled with the current system in China has produced three sets, but the quality of domestic products and imported products compared to high-end is still a large gap, it is expected that the new device is put into operation, will step butyl rubber or butadiene rubber footsteps, device utilization also will be significantly reduced.

3. Synthetic rubber prices will remain within a narrow range, the average price will decline year on year

Factors that affect the price of synthetic rubber, in addition to the macro economy, oil prices, but also includes the supply and demand fundamentals, and alternatives to natural rubber prices, the main raw material butadiene.

From the current supply and demand fundamentals, serious excess supply of synthetic rubber market is not conducive to rising prices of synthetic rubber.

Alternatives to natural rubber prices from trend, synthetic rubber prices bearish pressure. A few years ago the sharp rise in prices and high profits, stimulate the domestic rubber producing areas planted enthusiasm, these rubber trees have been tapping into the production cycle, but the world rubber demand has not fully recovered, nearly two years of natural rubber stock levels are constantly increased. Overall, the natural rubber supply side more relaxed, not conducive to price increases, thus bearish synthetic rubber prices.

From the butadiene price, but also one of the adverse factors affecting prices of synthetic rubber. Although the long term, ethylene feedstock butadiene ratio will make lightweight and ethylene production declined, but butadiene demand growth in recent years has declined. Other routes while increasing raw material butadiene capacity will make up for slowing the growth of butadiene extraction method. Oxidative dehydrogenation of butene butadiene plant built in the country after another individual devices is currently only in the low-load operation, other devices in the test that is in the parking postpartum state, there are still a lot of construction equipment. And this process is much higher than the cost of extraction and processing method, it is expected that oxidative dehydrogenation of butadiene breakeven point is a critical pressure level butadiene recent price movements. Butadiene synthetic rubber prices is not conducive to price movements.

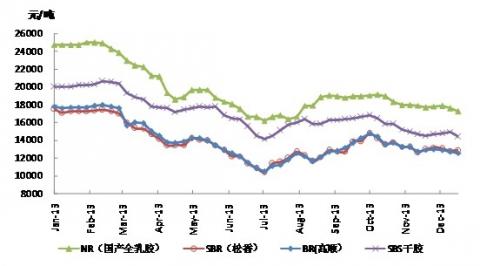

In addition, Lanxess, Japan JSR, Zeon and other companies have built in Singapore and other regions synthetic rubber plant, and have been put into operation, and its face is also the Asian market, especially China market.Establishment of the ASEAN Free Trade Area for its convenience outlet provides preferential conditions for the listing of these products is not conducive to rising prices of synthetic rubber. 2013 main varieties of synthetic rubber price trend in Figure 1.

Figure 1 2013 main varieties of synthetic rubber prices

Translated by Google Translator from http://market.cria.org.cn/25/19133.html