ubber has been grown traditionally in the Low country Wet Zone covering the South Western, Southern and Central parts of Sri Lanka, though the Low and mid elevations in the Intermediate and Dry zones are also being explored now with varying degrees of success. This tract is however, now reaching a level of saturation for rubber cultivation and the scope of further expansion is very much limited

The area under cultivation had fallen sharply since the 1970s, when over 200,000 hectares were under rubber. By 2004, only 115,300 ha were under rubber. This increased to 124,300 ha in 2009. The total extent is now 127,500 hectares of which the area in tapping is 101,720 ha . The area under tapping increased from 89,000 in 2004 to 95,300 in 2009 to 101,720 in 2011.

Although the planting cycle in rubber plantations is normally 30 years with a 3 % re-planting rate per year, yet, the area under re-planting has been very modest. It was 5200 ha in 2007; 1000 ha in 2008; and 3,600 ha in 2009; 6500 in 2010 and 7100 in 2011. Increases in rubber prices seem to act as a discouraging factor on re-planting.

Attempt has also been made to increase the new planting area by 40,000 ha, but this appears to be unlikely to be achieved due to technical as well as non-technical reasons.

Attempt has also been made to increase the new planting area by 40,000 ha, but this appears to be unlikely to be achieved due to technical as well as non-technical reasons.

In the traditional area, progress in production will have to largely come from productivity improvement achieved through replanting of old and low yielding areas and better agro-management of mature plantations. There are still wide gaps in productivity. National productivity is much below the achievable. Non-traditional areas so far identified are only marginally suitable and rubber cultivation in none of these areas can be expected to be ideal.

Non-traditional areas

Although the GOSL and the Rubber Industry are very keen to extend rubber growing to non-traditional rubber growing areas in Uva and in the Northern and Eastern provinces where land and labour are assumed to be non-limiting factors, yet, there are several constraints to successful implementation of such plans.

The non-traditional rubber growing areas have been focused in many development projects with the aim of uplifting the rural poor but with very little success. Uva province is still the poorest with poverty Head Count Index1 (HCI) of 27%, while Moneragala and Badulla districts have HCIs of 33.2% and 23.7%, respectively and being ranked as 2nd and 4th districts based on this index (Department of Census and Statistics, 2009.

Under such circumstances, there is a risk of resource wastage unless proper planning is done at the initial stages of rubber development programmes in these areas. This is especially important in the development of the smallholder sector where resource wastage is expected to be more due to poor knowledge and non-adoption of technical recommendations related to rubber planting and processing. Further, many development programmes have failed due to insufficient attention on the needs and thoughts of the community, in the planning process.

Being a relatively new initiative, there is a high degree of uncertainty about the sustainability of the attempt in expanding rubber into less suitable areas in terms of agro climatic condition, due to inadequacy in knowledge on environmental, socio-economic, technological and institutional aspects.

A pilot study under taken in Moneragala highlights many issues.

Socio-economic

Some of the key socio-economic characteristics of smallholder farmers indicate the younger generation’s preference for rubber cultivation in these areas. The proportion under 50 years of age is more under categories of “potential farmer” and” farmers who own immature holdings” compared to” farmers who own mature holdings”. The education levels of the smallholders when categorized into (1) Primary (2) Ordinary level qualified (3) Advanced Level qualified or higher, more than 50% of the farmers have only primary level education. This is a limiting factor to the efficiency of rubber farmers in the non-traditional rubber growing areas.

Some of the key socio-economic characteristics of smallholder farmers indicate the younger generation’s preference for rubber cultivation in these areas. The proportion under 50 years of age is more under categories of “potential farmer” and” farmers who own immature holdings” compared to” farmers who own mature holdings”. The education levels of the smallholders when categorized into (1) Primary (2) Ordinary level qualified (3) Advanced Level qualified or higher, more than 50% of the farmers have only primary level education. This is a limiting factor to the efficiency of rubber farmers in the non-traditional rubber growing areas.

The higher percentage with a monthly income of less than Rs. 10,000 (Approx. US$ 91) should also be regarded as a bottleneck for the adoption of recommended technologies and therefore proper monitoring systems need to be adopted in disbursement of subsidies in order to ensure proper utilization of state funds and also that the subsidies reach the appropriate category of farmers.

There appears to be some improvement in the economic status of mature farmers. A higher proportion of farmers are above the monthly income level of Rs.25,000/= (Approx.US$ 227) compared to ‘potential’ and ‘immature’ categories of farmers.

Technical knowledge

The technical knowledge on immature land’s maintenance programmes appears to be the lowest in the villages tested with an average of only 21%. Knowledge on disease control measures is also poor indicating an average in the range of 34%. Knowledge on 3 other field activities viz. planting related activities, intercropping and soil fertility management appear to be moderate, 49%, 45% and 50%, respectively in the selected villages. Knowledge buildup on immature upkeep requires drastic improvements in most of the holdings, as scores above 60% have not been recorded in any of the holdings. Knowledge on tapping related activities is also inadequate in general since the average awareness scores for both general and technical knowledge on tapping appear to be low and is below 40%.

Status of lands

In immature holdings, the recommended stand of 500 plants/ha has not been achieved and it has come down to an average of 427 per ha. for various reasons. Impact of drought appears to be the most prominent cause with an average of 67%, and poor quality of plants provided is understood to be in the range of 14%, are the cause for plant casualties. Intercrops are grown in 79% of the immature rubber lands, but Cover crops were not seen in 97% of the immature lands. Stone terraces were seen in 37% of the fields while drains are present in 23% of the immature lands.

Regular weed control measures appeared to be practiced in 98% of the immature holdings. However, the recommended method of weed control; viz. around the trees was practiced by 22% of the farmers, only. All the farmers apply fertilizesr that are supplied to them through the subsidy. Fertilizer application is normally done in 78% of the holdings, leaving 22% of non adopters. Method of application is according to the recommended practice in 60% of the holdings, while 32% appear to be applying fertilizer around the trees.

Mature plantings

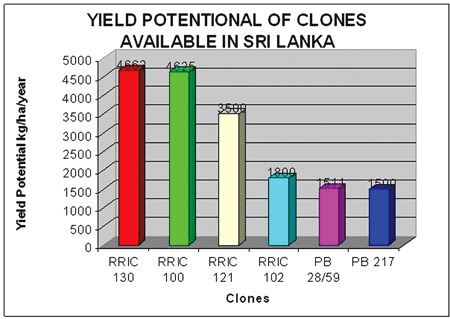

In mature plantations, the majority of the farmers (53%) do not appear to know any thing about the clone in their field. Clone RRIC 100 are being used in 23% of the lands and 17% of the lands still have PB 86, a clone withdrawn from the recommended list, long ago.

The remaining extents had clones, RRIC 121 and RRIC 102. The plant stand in the mature areas has come down further, to an average of 414 trees/ha compared to 500 trees/ha planted during establishment period in the field.

Further, the tappable trees are also in the range of only 368 trees/ha for various reasons.

Drought had been the main cause for the reduction in the stand per ha in the absence of drought management practices by the farmer. Poor quality of plants, besides animal and fire damages and tapping panel dryness (TPD) were identifiable in the field.

Different types of intercrops are present in 35% of the mature holdings. Among them, Cocoa and Banana appear to be more popular while pepper, sugarcane and cinnamon are also present in several fields. Diseases and other plant physiological disorders have not been identified in 44% of the holdings. But, in 38% of the holdings tapping panel dryness was observed and white root disease was also present in 19% of the holdings. Fertilizer application is being done in 54% of the mature holdings.

Method of application is according to the recommendation in 57% of the holdings, while 8% applied fertilizer around the trees.

Land issues

The majority of the respondent farmers in participatory studies were ‘potential’ rubber growers who had already received permits for rubber cultivation and were expecting to cultivate rubber. The major issue in most of the areas was related to planting material. Due to the high demand for planting material, poor quality planting material have been released to the farmers in certain occasions. Some farmers had difficulties in getting permits for rubber cultivation, as these have not been issued on time by the respective Divisional Secretariats. Nearly 53% of the farmers indicated that they occupy state owned land on lease or having ‘Swarnabhoomi’ or ‘Jayabhoomi’ deeds and some appear to be encroachers. Further, delay in subsidy payments, poor knowledge on rubber farming, marketing problems and lack of training facilities were also raised as major issues by some farmers.

Production Efficiency

The production efficiency levels estimated using the Cobb-Douglas production frontier ranged from 17% to 96%, with an average value of 59%. This suggests that 41% of the potential maximum productivity is lost due to inefficiency of farmers in the Moneragala district.

Nearly 48% of the growers are above the average value of 59%. Relatively a higher percentage of farmers (14.6%) were in the efficiency range of 81% to 90%. About 6% of the farmers were above the 90% efficiency level.

The effect of farm and farmer specific factors on inefficiency was simultaneously estimated with the profit frontier. Among the variables used in the analysis, tapping panel (PANEL), labour for tapping (TAPLAB) and dummy for education (DOL) were significant at the level of 0.01 while extent of land (EXT), intensity of tapping (TAPINT) were significant at 0.05 level. The extent of land (EXT) had a significant estimate with a negative sign, which suggested that higher the efficiency with higher the extent. The lands with extents less than 1.5 ha has efficiency values of 59% while an average efficiency of 71% is seen in lands with extents greater than 1.5ha. Tapping intensity is another important factor which affects productivity. Those who practice the recommended level had high efficiency levels.

The average efficiency obtained by practicing recommended tapping intensity was 60% while those who were not following the recommendations had an efficiency level of 43%. Tapping panel (PANEL) also had a significant negative estimate depicting those who tap on the virgin panel (A & B) have higher efficiency levels. The average efficiency observed in the virgin panel was 62% while it was 52% with the renewed panels.

Labour

Hiring of outside labour had no effect on the efficiency. However, those who tap their own land have higher efficiencies with respect to intake per tapper. The average efficiency in the lands tapped by owners themselves was 61% while when tappers were hired it was only 55%. Distance and age of farmers did not have any significant effect on efficiency.

Further family labour involvement (the number) and the use of different clones dod not have any effect on the farmers efficiency, as clone selection and distribution are normally done as a component of subsidy. Those who had an education level above O/L have an average efficiency value of 62% while for those who did not have o/L education, the average was 57%.

Therefore, for achieving production efficiency, reallocation of resources with changing economic conditions is vital. Education provides this by enabling the farmers to (a) perceive that a change has occurred (b) collect, retrieve and analyze useful information (c) drawing valid conclusions from available information and (d) act quickly and decisively.

Although, Sri Lanka is the eighth largest producer of NR in the world and ranked fourth in terms of productivity, yet, there are many unresolved issues in Smallholdings. Over 62 % of cultivation is in smallholdings. Unlike in tea smallholdings, low productivity levels in this sub- sector have kept rubber cultivation vulnerable to overexploitation, when prices are high, and abandonment, when prices are low.

Prima facie, it appears that the main cause for low national rubber productivity is the high percentage of smallholders of less than one acre. This is also the case for other countries with higher productivity experiences. Experiences of smallholder development programs in other NR producing countries have also shown that more profitable and well informed farmers are also more likely to supply better quality raw material and invest in timely replanting ensuring a regular supply.

Rubber is grown on smallholder lines in Thailand, 90% of the extent; and India, 89% of the extent and 91% of total production. What is seen in contrast is the careful management of smallholder cultivation by the State – recognizing and providing for appropriate institutional support to help smallholders. Smallholder support focuses on help to obtain the right planting material; continuously educating and monitoring smallholders in correct planting, maintenance and tapping practices; and creating support for marketing activities.

The value chain assessment generally shows that the failure of an appropriate and working technical support and monitoring system has resulted in:a) Low spread of clonal planting material, b) Failure to halt spread of low yielding clones, c) Poor cultivation practices which result in 50% – 70% less.,d) Proliferation of poor tapping practices which reduce the tapping lifespan by around 10 years, i.e. 50% and e) Very limited recognition of the environmental benefits of rubber agro forestry in designing replanting programs.

Another drawback is the absence of village or even district level financing mechanisms for smallholders. This has resulted in smallholders’ inability to obtain a better share of price. On average although processors pay around 80 to 85% of FOB for raw material less than 50%, often as little as 30% goes down to the actual producer in some countries.

It is therefore considered useful in providing the following services to growers in non-traditional new planting areas, majority of whom are expected to be smallholders:

1. Setting up certified nurseries at local level and support of technical information sharing system

2. Training of key farmers and setting up farmer groups/supporting already established farmer groups

3. Provision of technical support service and strengthening local extension services

4. Training of producers and tappers and crop share workers, and

5. Setting up micro credit systems/linkages for producers

Rubber in the Eastern and Northern regions is a totally different story. Most of the prospective rubber growers may not have even seen a rubber tree.

Moreover, the immature period of plantings can be much longer, may be even 8-9 years. Therefore it is important that multi-cropping systems suitable to the farmers should be developed before embarking on large scale plantings. They may not be willing to wait for 8-9 years without any income from their farms.

Y1; Maximum realizable yield on the basis of theoretical consideration (10000kg/ha)

Y2; Maximum yield obtained from small scale experimental plants (3500 kg/ha)

Y3; Maximum yield obtained from a commercial plantation (2250 kg/ha)

Y4; Average National Yield (1558 kg/ha)

Siurce: http://www.dailynews.lk